基于高速IGBT的100kHz高压-低压DC/DC转换器

编者按:本文分析了一种基于高速IGBT的软开关移相全桥带同步整流的DC/DC转换器。移相全桥拓扑的软开关技术是混合动力汽车和电动汽车高压-低压DC/DC转换器的主流关键技术。业界早期使用MOSFET作为主功率单元,随着该DC/DC转换器的功率需求逐渐增大,基于MOSFET的设计系统效率急剧下降,已经不能满足应用要求。本文采用英飞凌第三代高速IGBT和快速二极管功率模块F4-50R07W1H3作为DC/DC转换器核心主功率单元,采用无核传感技术的驱动芯片1ED020I12FA2,使开关器件工作在100kHz的软开关

3.2 开通损耗分析

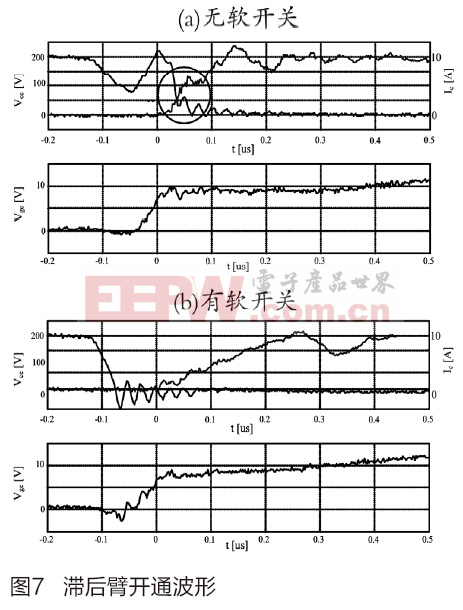

如图7所示,尽管大多数负载点可以实现软关断,但是在轻载时由于原边电流较小,储存在变压器漏感的能量较小,不足以使滞后臂实现软关断。从整体效果来看,主工作区间良好实现了软关断,IGBT的极低的输出电容特性使得整个系统在没有外置谐振电感的情况下实现了主工作区间的软关断,系统损耗由此明显降低,这也是由前文提到的IGBT芯片面积远小于MOSFET所决定。

3.3 效率测试与分析

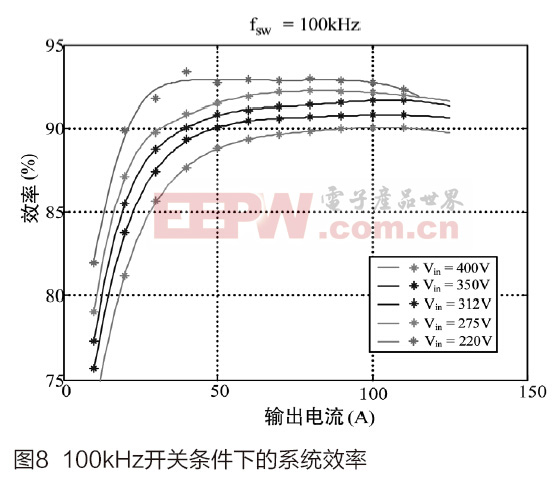

经过前文对开通和关断状态的分析,进一步测试了整个系统的效率,效率的测试方法采用测量输入电压、输入电流、输出电压、输出电流并计算输入功率和输出功率的方法得到。输入电压采用电压表测量,输入电流采用高精度分流计测量,输出电压电流功率数据从电子负载中得到。最终测试结果显示,在很宽的电压输入范围里,系统都能超过90% 的效率。图8展示了输入电压220V到400V,输出电流20A到110A的系统效率曲线,其中系统效率较高的区域是电压输入较低的区域。最核心的负载段,即30%到70%的负载段是系统工作最典型的使用工况,也是本设计最重要的设计目标段,该段效率也达到了90%以上。

4 结论

当代高速IGBT(如英飞凌HS3系列),对比传统的沟槽栅场终止IGBT,在不增加集电极到发射极饱和压降的情况下,拖尾电流和关断损耗得到显著改善,显著地改善了沟槽栅。通过电路设计和实际测试,在这种软开关式移相全桥DC/DC转换器的应用中实现了替代超级结MOSFET的可能性,同时在功率较高的工况超越了超级结MOSFET的性能,同时芯片面积比MOSFET大幅缩小,因此芯片成本也会降低。

本设计采用13:1的匝比,配合移相全桥和全波同步整流的拓扑结构,以及无谐振电感特性,实现了220V到400V功率范围,93%的最优效率,以及非常平缓的效率下降平台,为高压-低压DC/DC变换器的设计提供了一种新的功率器件设计选择方向。

参考文献:

[1]S.M.N.Hasan, M.N.Anwar, M.Teimorzadeh, D.P.Tasky, “Features and challenges for Auxiliary Power Module (APM) design for hybrid/electric vehicle applications”, IEEE Vehicle Power and Propulsion Conference (VPPC) 2011, 6-9 Sept. 2011

[2]L. Mweene, C. Wright, and M. Schlecht, “A 1 kW 500kHz front-end converter for a distributed power supply system," Power Electronics, IEEE Transactions on, vol. 6, no. 3, pp. 398-407, 1991

[3]R.Redl, L.Balogh, D.W.Edwards, “Optimum ZVS Full-Bridge DC/DC Converter with PWM Phase-Shift Control: Analysis, Design Considerations, and Experimental Results”, Applied Power Electronics Conference and Exposition 1994, Ninth Annual Conference Proceedings 1994. pp.159-165, 13-17 February 1994.

[4]F. Krismer and J. Kolar, “Efficiency-optimized high-current dual active bridge converter for automotive applications," Industrial Electronics, IEEE Transactions on, vol. 59, no. 7, pp. 2745-2760, 2012.

[5]G. Deboy, N. Marz, J.-P. Stengl, H. Strack, J. Tihanyi, and H. Weber, “A new generation of high voltage MOSFETs breaks the limit line of silicon,” in Electron Devices Meeting, 1998. IEDM '98. Technical Digest., International, pp. 683-685, 1998.

[6]I. Widjaja, A. Kurnia, K. Shenai, and D. Divan, “Switching dynamics of IGBTs in soft-switching converters,” Electron Devices, IEEE Transactions on, vol. 42, no. 3, pp. 445–454, 1995.

[7]R. Wu, J. Wen, J. Wu, Z. Chen, C. Peng, and Y. Wang, “Analysis of power losses in voltage source converter with new generation IGBTs," in Computer Science and Automation Engineering (CSAE), 2012 IEEE International Conference on, vol. 1, pp. 674-678, 2012.

[8]T. Laska, M. Munzer, F. Pfirsch, C. Schaeffer, and T. Schmidt, “The field stop IGBT (FS IGBT). a new power device concept with a great improvement potential," in Power Semiconductor Devices and ICs, 2000. Proceedings.The 12th International Symposium on, pp. 355-358, 2000.

[9] H. Huesken, D. Chiola, and T. Kimmer, “A new IGBT family optimized for high switching speed," in Proceedings of PCIM Europe Conference, 2010.

[10]D. Chiola, H. Hsken, and T. Kimmer, “High speed IGBT with MOSFET-like switching behavior," in Proceedings of PCIM Europe Conference, 2010.

[11]T. Kimmer and E. Griebl, “Trenchstop5: A new application specific IGBT series," in Proceedings of PCIM Europe Conference, 2012.

[12]Erickson, R.; Maksimovic, D., Fundamentals of Power Electronics. University of Colorado Boulder, 2 ed., 2001. ISBN: 0-7923-7270-0.

加入微信

获取电子行业最新资讯

搜索微信公众号:EEPW

或用微信扫描左侧二维码